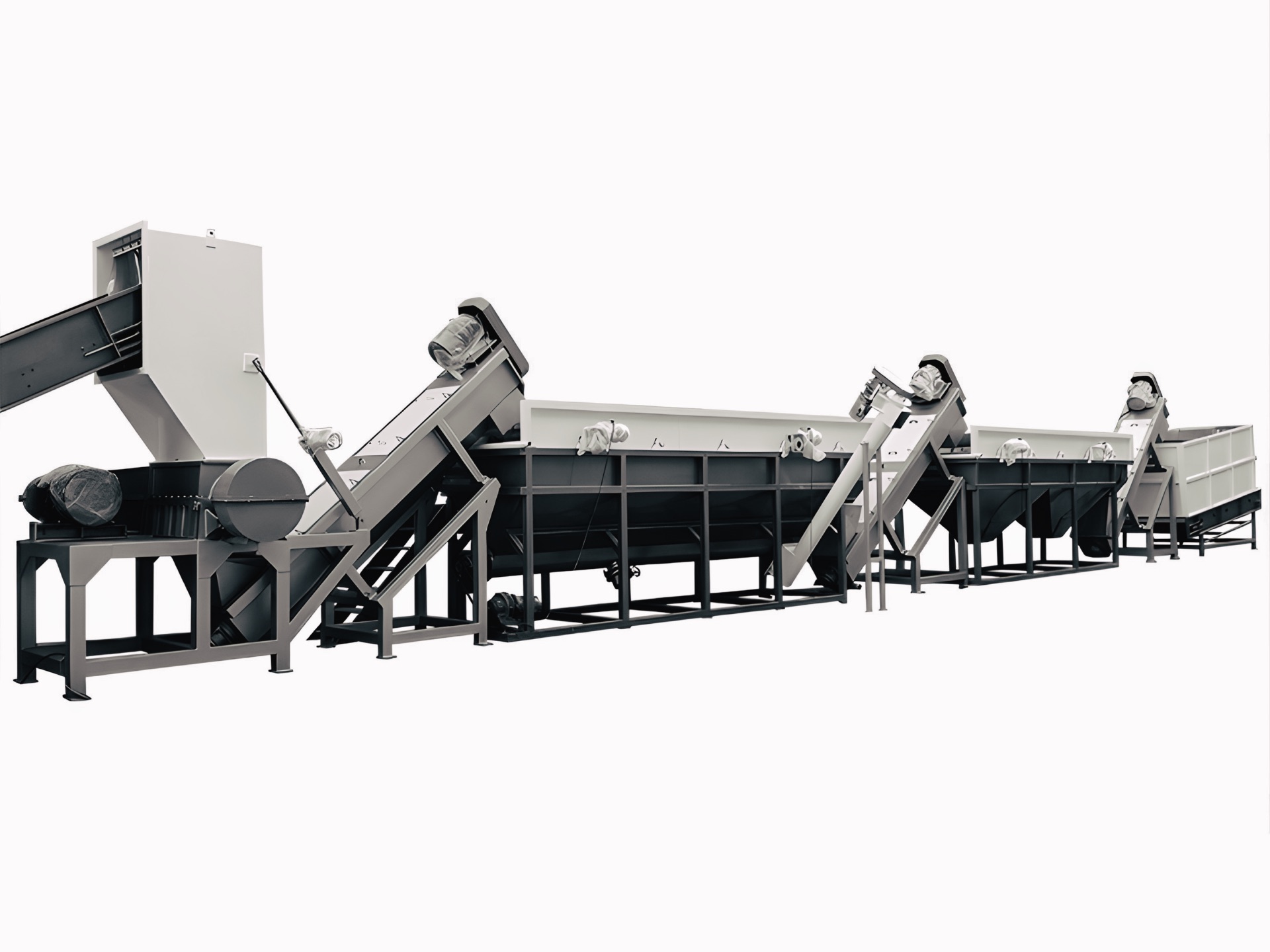

PE film, encompassing low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), and high-density polyethylene (HDPE), is ubiquitous in applications like shopping bags, agricultural films, and industrial wraps. Recycling is vital for reducing environmental impact, and the PE film washing line is central to this, cleaning and preparing used film for reuse. Industry standards, such as those from the Association of Plastic Recyclers (APR) – PE Film, guide design and processing to maximize recyclability.

PE film washing line process