PP/PE Film Recycling Washing Line

Introducing the innovative PET Bottle Recycling Machine, designed to streamline the recycling of polyethylene terephthalate (PET) bottles. This advanced machine efficiently crushes, shreds, and sorts PET bottles, transforming waste into valuable recycled material. With cutting-edge technology at its core, it not only reduces environmental impact but also boosts productivity in recycling facilities.

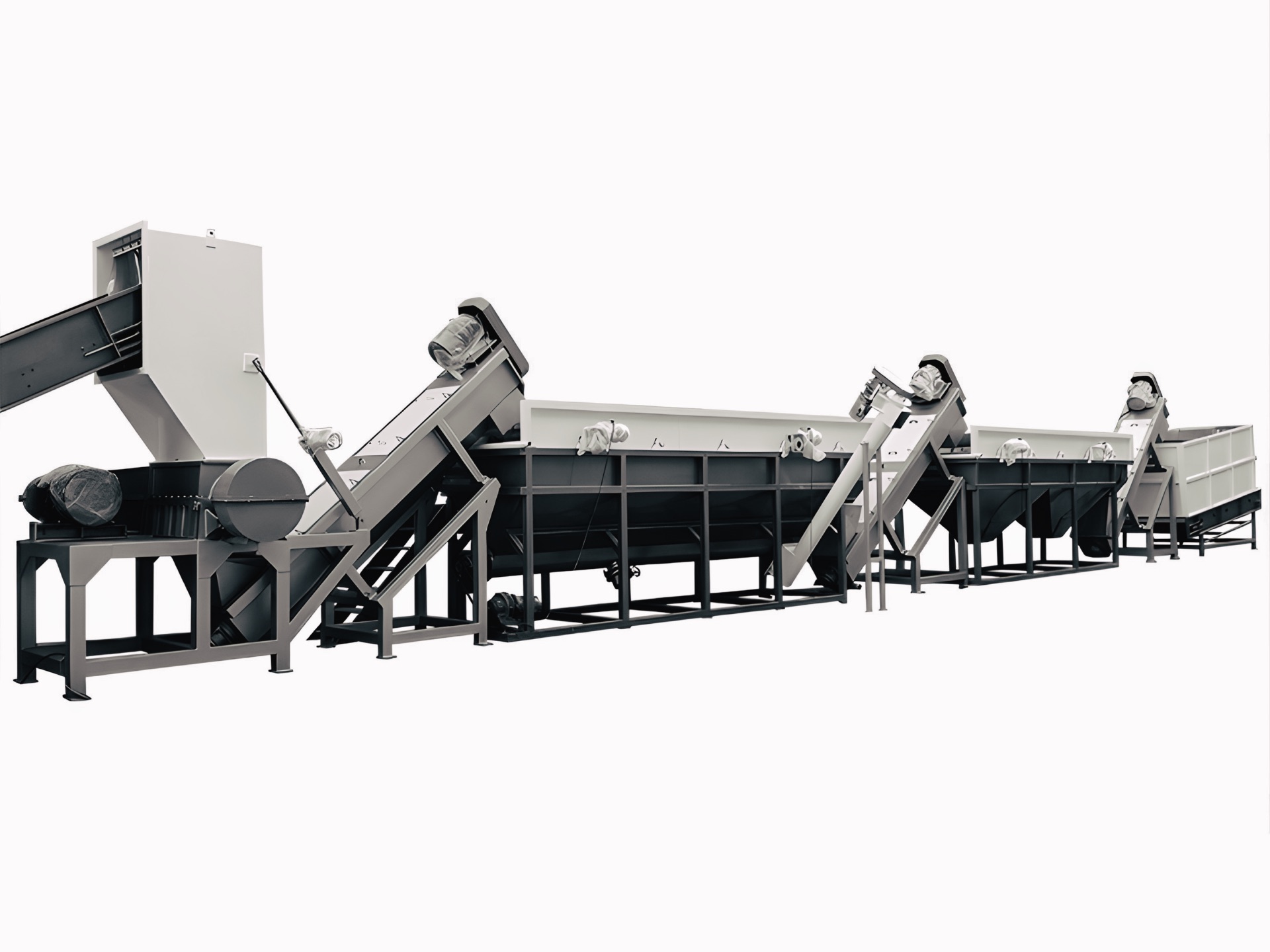

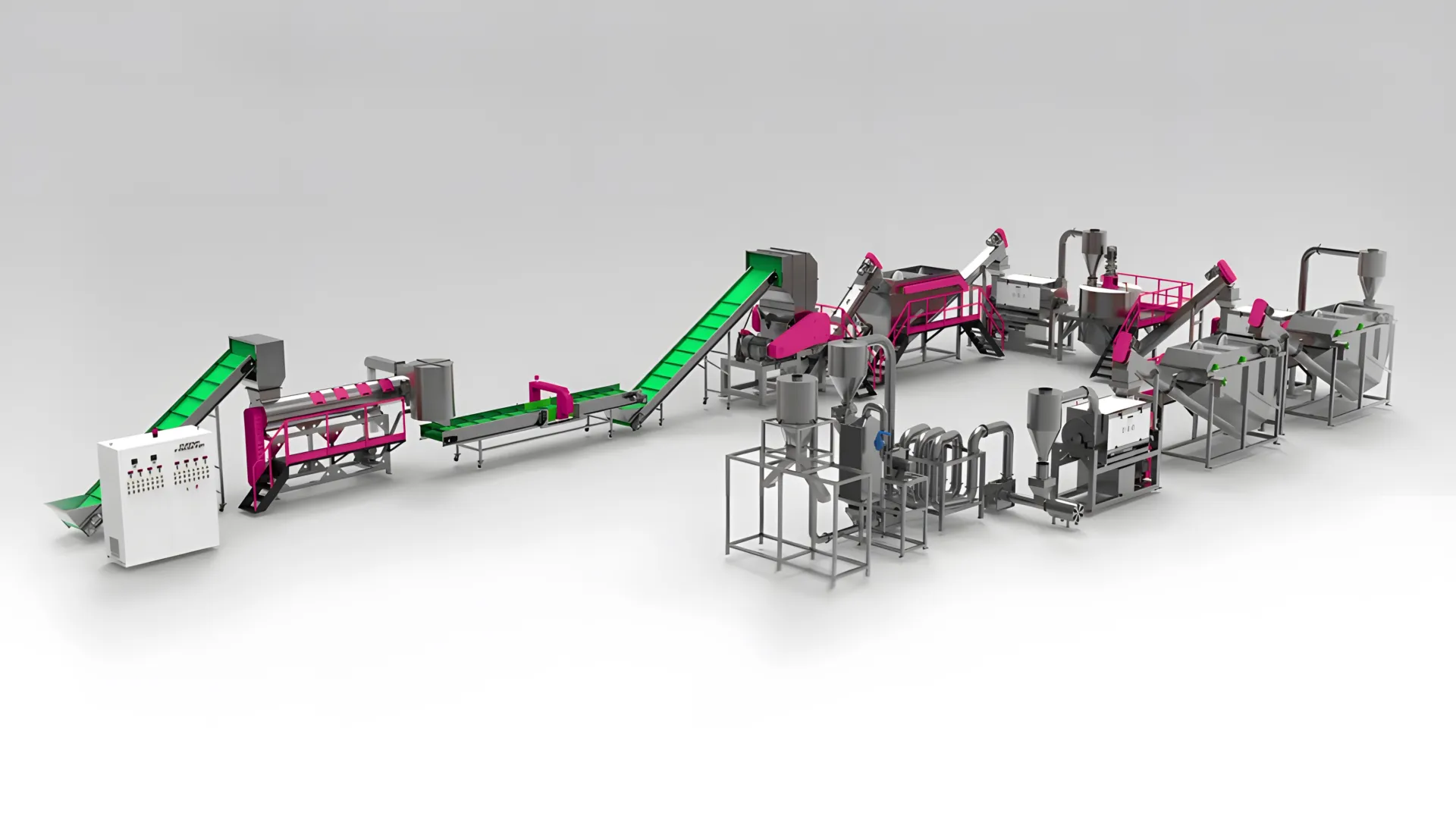

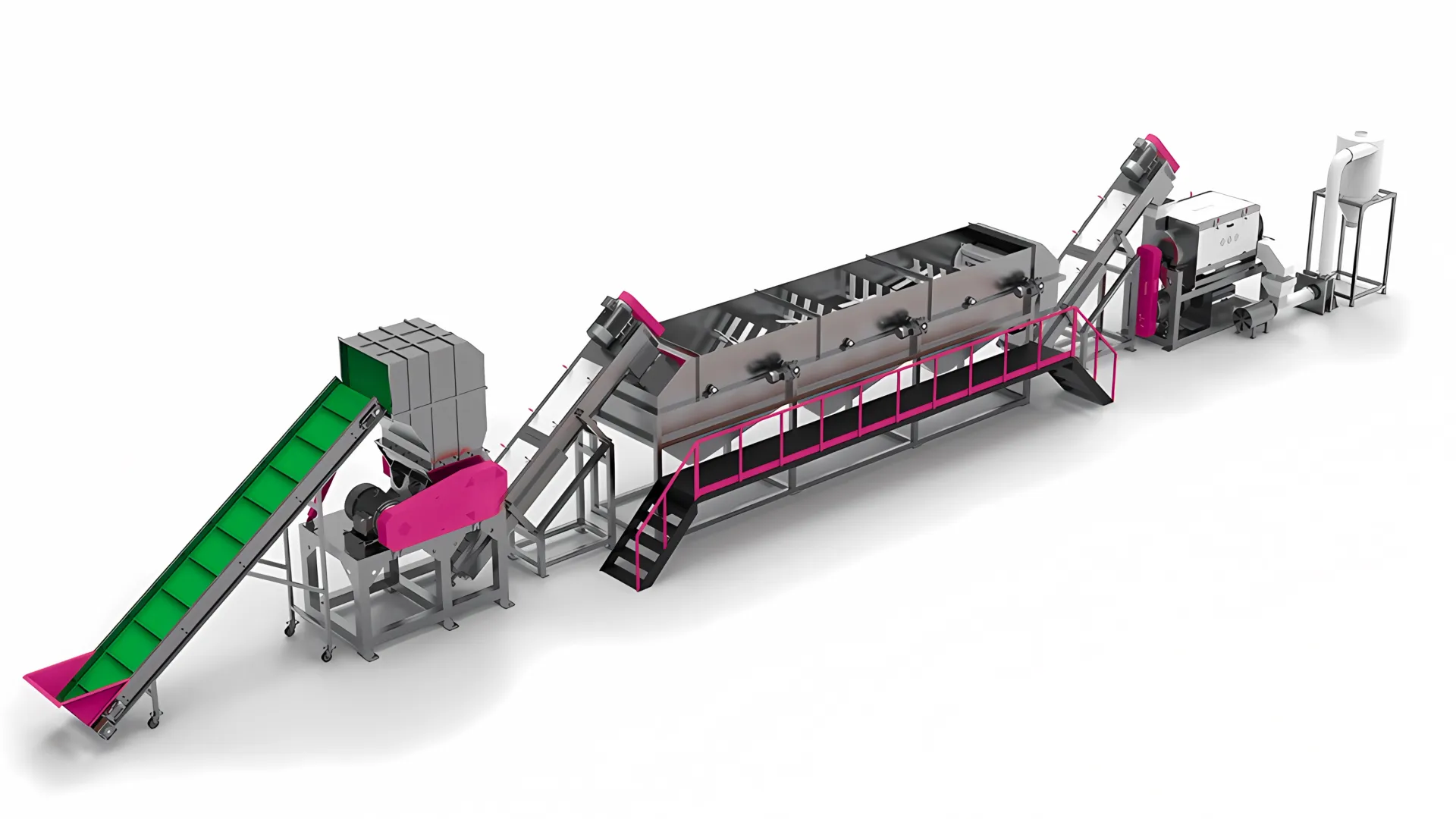

Our company specializes in providing efficient and sustainable plastic film recycling solutions. We understand the critical need to balance environmental responsibility with the increasing demand for plastic pellets. Our comprehensive plastic film washing line is designed to process polypropylene (PP), polyethylene (PE), and various other types of plastic films. Utilizing cutting-edge technology, our fully automated recycling line integrates a series of machines strategically arranged to maximize efficiency and minimize waste.

Learn more about plastic film recycling and its benefits.

Discover the eco-friendly advantages of non-woven bags.

Explore the sustainability of artificial grass solutions.

Understand the recycling process of BOPP films.

Find out how mulch plastic film contributes to agriculture.

Learn about the durability and recyclability of woven bags.

Large contaminants are removed, and materials are prepared for optimized processing in subsequent stages, enhancing overall efficiency.

Materials are uniformly reduced in size, allowing for more effective washing and preparation for recycling.

High-temperature washing combined with precise chemical agents removes oils, adhesives, and stubborn contaminants from PE films and fabrics.

Advanced separation removes lightweight contaminants and isolates high-quality plastic materials for further processing.

Thorough rinsing and efficient dewatering prepare the materials for the final drying phase, ensuring optimal cleanliness.

Materials are thermally dried to achieve a low moisture content, resulting in high-quality output ready for reuse in advanced applications.

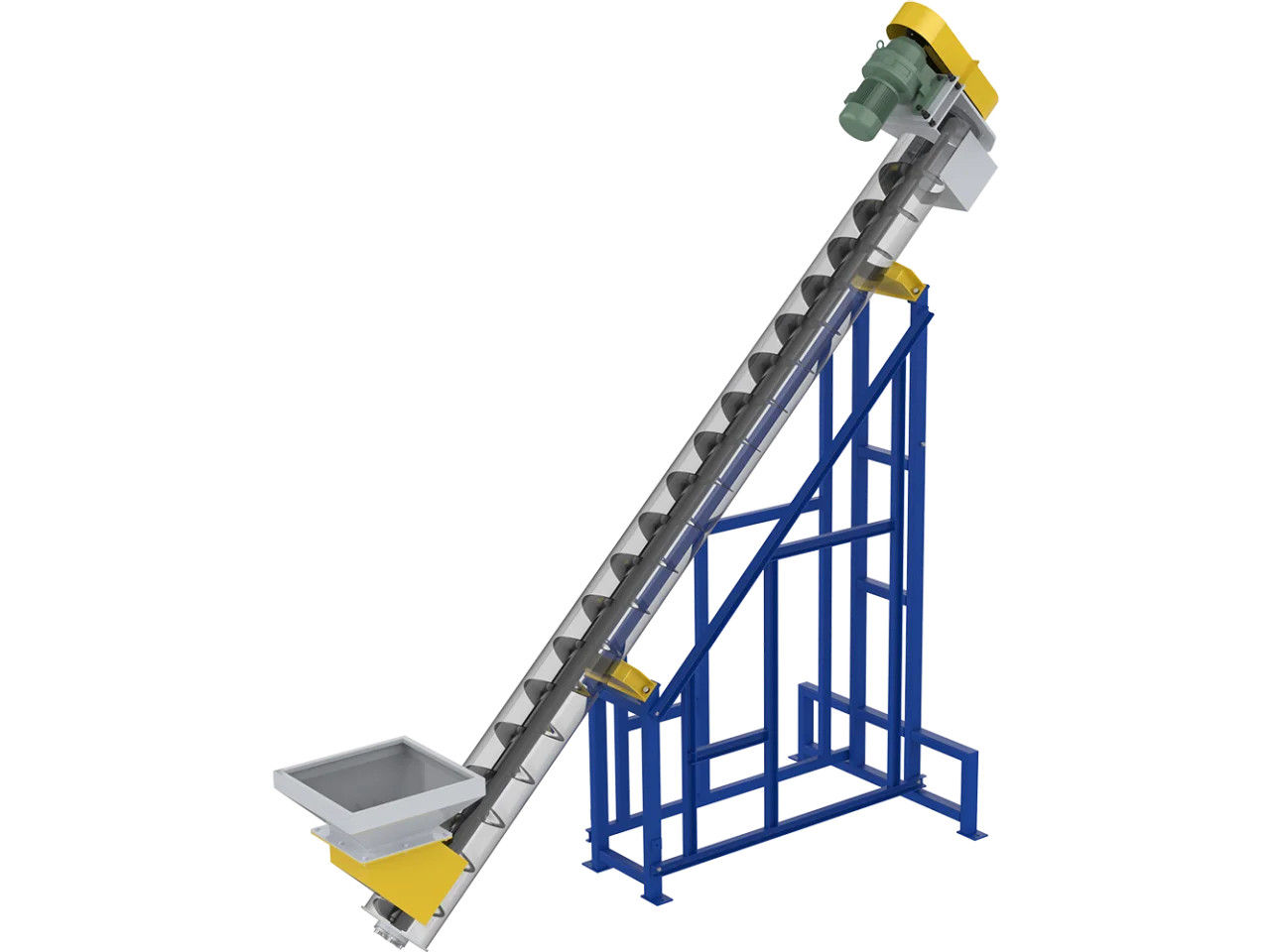

The Screw Feeder is designed for durability and efficiency in material handling processes.

Primary Functions:

The Single-shaft Shredder is engineered for efficient shredding and size reduction of a variety of materials, including plastics, wood, and general industrial waste.

Primary Functions:

The Wet Plastic Granulator is an upgraded version of our general-purpose granulators, designed for efficient cutting and pre-cleaning of plastic bottles, films, and rigid materials.

Primary Functions:

The Friction Washer is designed for efficient cleaning and transportation of plastic flakes, films, and regrind materials.

Primary Functions:

Our Floating Separation Tank is designed to efficiently segregate PP and PE plastics from co-mingled streams while simultaneously cleaning the materials for further processing.

Key Features:

The Hot Washer is specifically designed for cleaning plastic films and fabrics with oil stains, adhesives, and other persistent contaminants. It features an integrated heating system, eliminating the need for an external steam generator, and ensures effective cleaning with optimized chemical agents.

Key Features:

Our Centrifugal Dryer Dewatering machine is a highly efficient, low energy consuming equipment designed to partially remove water from plastic materials using centrifugal force. It’s an essential first step in PE film and PET bottle washing lines.

Key Features:

Our Pipe Dryer is designed for efficient moisture removal through dehydration, ideal for plastic film and PET washing line. It’s an essential final step in reducing moisture levels to below 3%.

Key Features:

The Film Squeezer, also known as the Squeezer Drying Machine, is engineered for efficient dewatering and compressing of washed plastic films, including polyethylene (PE) and polypropylene (PP). This machine is essential in recycling lines, significantly reducing moisture content and material volume to enhance downstream processing.

Primary Functions:

Reduced water and energy consumption, minimizing environmental impact.

Superior cleaning for high-grade recycled materials, ensuring premium results.

Capable of processing various rigid plastic types, offering unmatched flexibility.

Ready to upgrade your plastic recycling capabilities? Contact our team of experts today for a customized solution.

Get a Quote

Our rigid plastic recycling lines provide an efficient and cost-effective solution for processing various types of rigid plastics, such as HDPE bottles, lamps, pipes, and more. Designed for handling dirty, post-consumer plastics, these systems ensure thorough granulation, cleaning, and recycling. The result is high-quality, fully cleaned plastic regrinds, ready for reuse in manufacturing processes. Our recycling lines are available in capacities ranging from 500 kg/hr to 2000 kg/hr.